Typical modular steel panel sound enclosure design includes the use of a tongue and groove or H jointer connection to assemble the enclosures. This typically means the steel panels are the structure to support the roof panels and they are assembled in progressive panel assembly and all joints include angle flashing. This is a good simple design.

Typical modular steel panel sound enclosure design includes the use of a tongue and groove or H jointer connection to assemble the enclosures. This typically means the steel panels are the structure to support the roof panels and they are assembled in progressive panel assembly and all joints include angle flashing. This is a good simple design.

The typical disadvantages are the panels are cumbersome to remove. You may need to disassemble the roof and progressively remove side panels for major maintenance. This leads to adding more costly doors to the enclosure for ease of access and adding size and interior clearance to move around inside the enclosure. This is OK if you have a lot of space.

Advantages of Removable Panels on Your Sound Enclosure

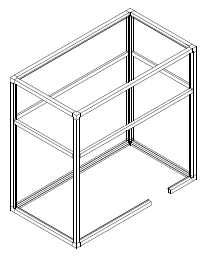

- The design starts with an aluminum extrusion with cast corner and end pieces to from a stand-alone self-supporting frame

- Then the sound enclosure panels are “Box” panels, meaning no tongue, grove or H jointer

- On the frame at the top and bottom are 1/4 turn fasteners that hold the enclosure panels in the extrusion frame

- Handles are installed in the front face of the panels to aid in removing them

- The stand-alone frame allows you to remove the any side or roof panel for access to the equipment – No doors needed!

- Also with available access to the equipment anywhere, you can make the enclosure much smaller because someone will not need to move around inside.

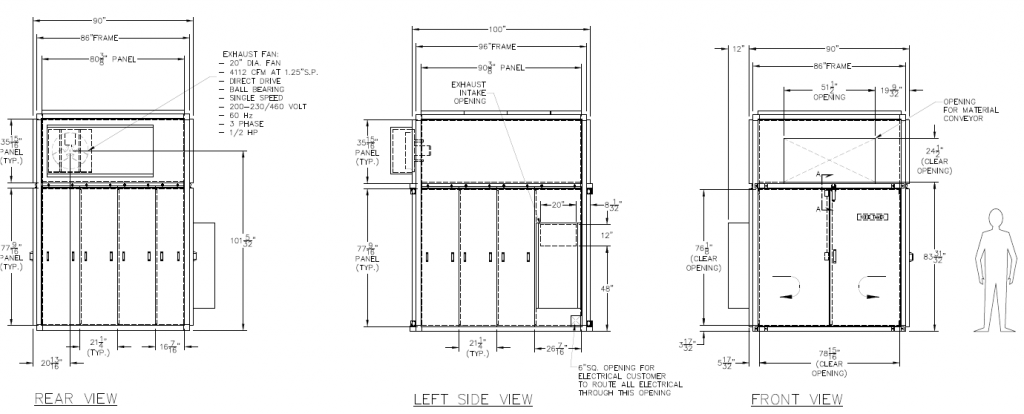

Modular Sound Enclosure Features:

- 16 gauge galvanized steel wall and roof panels (4” bent panel construction)

- 4”-4#/cu.ft. mineral wool (Bagged) lining with 22 gauge galvanized steel perforated cover

- Factory pre-assembled panels

- Alum-A-Frame Series 50 frame with die cast aluminum corner joints and pre-cut aluminum extrusion-mill finish, 0.078″ wall thickness

- All wall panels (with the exception of header panels and panels with ventilation hoods) are removable and are secured to the frame from the outside of the enclosure with panel retainers. All other panels are fixed and are secured to the frame from the inside of the enclosure with sheet metal screws. All sheet metal screws to be located and secured by others at the time of installation.

- (2) B40FGC panel retainers and (2) MFG85 small handles for each removable wall panel

- (Includes installation of inserts for panel retainers and handles.)

- (2) MFG85 small handles for each removable roof panel (Includes installation of inserts for handles.)

Applications Ideal for Removable Panel Sound Enclosures

- PD Blowers

- Plastic Grinders

- Plastic Granulators

- Pumps

- Hydraulic Power Units

- Chillers

- Shredders

- Vacuum Pumps

Please call eNoise Control to discuss your noise control application!