Waste Water Plant Noise Control

Waste water treatment facilities are equipped with many types of machinery to help process the waste water. Compressors, pumps, and fans are the most common. Most facilities are constructed of painted concrete block walls and concrete floors that are easy to keep clean. Many units of noisy equipment operating in rooms with hard reflective surfaces is a combination that will make for a very noisy and unsafe work environment. Compressors, pumps, and fans are very noisy equipment and can easily bring a facility above the OSHA limits for sound. Engineering controls should be used to control the sound levels of the equipment for worker safety and to prevent hearing loss.

Waste water treatment facilities are equipped with many types of machinery to help process the waste water. Compressors, pumps, and fans are the most common. Most facilities are constructed of painted concrete block walls and concrete floors that are easy to keep clean. Many units of noisy equipment operating in rooms with hard reflective surfaces is a combination that will make for a very noisy and unsafe work environment. Compressors, pumps, and fans are very noisy equipment and can easily bring a facility above the OSHA limits for sound. Engineering controls should be used to control the sound levels of the equipment for worker safety and to prevent hearing loss.

Acoustical Room Absorption

The waste water plant noise control solution is to add durable acoustic absorption to reduce the noise reflected off the walls, floors, and ceilings. This should be done in conjunction with acoustical sound curtain absorption and barriers around the noisiest areas or equipment or to line the walls of the room.

With the installation of acoustical absorption to a room, clients can expect a 3-8 dBA reduction. We recommend using a combination of two products to treat waste water treatment plant noise problems. Our UNC-10 sound curtain installed on the ceilings and UNC-25 covering the walls provides excellent noise mitigation. The UNC-25 product is a quilted facing with a vinyl barrier. This helps block the sound from reverberating off the walls of the pump room. The curtains have grommets across the top for suspension and velcro on the mating edges to insure a tight acoustic seal.

With the installation of acoustical absorption to a room, clients can expect a 3-8 dBA reduction. We recommend using a combination of two products to treat waste water treatment plant noise problems. Our UNC-10 sound curtain installed on the ceilings and UNC-25 covering the walls provides excellent noise mitigation. The UNC-25 product is a quilted facing with a vinyl barrier. This helps block the sound from reverberating off the walls of the pump room. The curtains have grommets across the top for suspension and velcro on the mating edges to insure a tight acoustic seal.

To the right you will find sound curtain datasheets for the UNC-10 and UNC-25 materials.

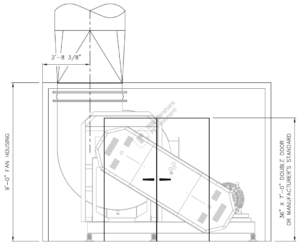

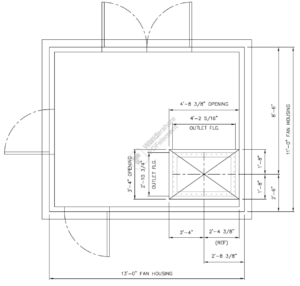

Sound Enclosures for Fans and Blowers

In wastewater treatment facilities, fans and PD blowers play a critical role in processes such as aeration, odor control, and ventilation. These machines often generate significant noise, which can lead to regulatory compliance issues, worker safety concerns, and environmental disturbances. Sound enclosures are a crucial solution for mitigating noise from fans and blowers in wastewater treatment plants.

Fans and blowers in wastewater treatment plants operate at high speeds and pressures, generating considerable noise due to air turbulence, mechanical vibrations, and motor operation. This noise can exceed permissible exposure limits set by organizations such as the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA). Excessive noise can cause hearing damage in workers, disrupt surrounding communities, and contribute to noise pollution.

Benefits of Sound Enclosures

Benefits of Sound Enclosures

Sound enclosures are engineered to contain and absorb noise, reducing its impact on the environment and personnel. The key benefits of sound enclosures include:

- Noise Reduction – Enclosures effectively attenuate noise levels, often reducing sound emissions by 15-30 decibels (dB) or more, ensuring compliance with regulatory noise limits.

- Improved Workplace Safety – By reducing excessive noise exposure, enclosures help prevent hearing loss and improve overall working conditions for employees.

- Enhanced Equipment Longevity – Enclosures can provide protection against external elements such as dust, moisture, and temperature fluctuations, prolonging the lifespan of fans and blowers.

- Regulatory Compliance – Many wastewater treatment plants must adhere to noise regulations set by local and federal agencies. Installing sound enclosures ensures compliance and avoids potential fines or operational shutdowns.

- Community Relations – Wastewater plants are often located near residential or commercial areas. Noise reduction measures help maintain good relations with nearby communities by minimizing disturbances.

Design Considerations for Sound Enclosures

The effectiveness of a sound enclosure depends on its design, materials, and installation. Several factors must be considered to optimize performance:

- Material Selection – Enclosures typically use of composite sound-absorbing/ sound blacking materials.

- Ventilation and Cooling – Fans and blowers require adequate ventilation to prevent overheating. Acoustic louvers, silencers, and forced ventilation systems can be integrated to maintain airflow while minimizing noise leakage.

- Access and Maintenance – Sound enclosures should have removable panels, access doors, or inspection windows to allow easy maintenance and monitoring of equipment without compromising noise control.

Typical Odor Control Fan Sound Enclosure Specifications

Provide enclosure including walls, roof, and acoustically insulated door for equipment access.

- When tested in accordance with ASTM C423, Standard Method of Test for Sound Absorption of Acoustic Materials in Reverberant Rooms, the panel assembly shall have at least a noise reduction coefficient (NRC) of 1.00

- When tested in accordance with ASTM E90, Standard Recommended Practice for Laboratory Measurement of Airborne Sound Transmission Loss of Building Partitions, the panel assembly shall have the following minimum Sound Transmission Class (STC) of 40.

- Include forced mechanical ventilation for cooling of enclosed equipment. Provide acoustic louvers or duct silencers to limit noise transmission through ventilation openings. Provide ventilation fan. Select fan airflow to provide whichever following ventilation criteria is greater: Ventilation to limit temperature rise within the enclosure to no more than 10°F above Ambient Ventilation to provide six (6) air changes per hour of ventilation

- Materials – Fabricate acoustic enclosure from acoustic panels with solid 16 gauge Type 304 stainless steel or aluminum outer shell, batt insulation, and 22 gauge perforated Type 304 stainless steel or aluminum inner liner.

Contact our team about your wastewater treatment noise issues at 888.213.4711 or send us an email to info@enoisecontrol.com.