Vertical Turbine Pump Sound Enclosures

Vertical Turbine Pumps are a specific centrifugal pump designed to move water from a well that is deep underground. Also known a deep well turbine pump or a line shaft turbine pump, Vertical Turbine Pumps are one of two main types of well pumps.

The two types of well pumps are vertical turbine pumps and submersible turbine pumps. While submersible pumps have the electric motor located underwater at the bottom of the pump, vertical turbine pumps have the motor located above ground, connected via a long vertical shaft to impellers at the bottom of the pump.

The pumps typically have a vertical electric motor. The pump end consists of at least one rotating impeller that is attached to a shaft and directs the well water into a diffuser casing called a bowl.

Multi-stage configurations use multiple impellers on the same shaft to create higher pressure that would be needed for deeper wells or higher required pressure (head) at ground level.

Vertical turbine pumps work when water enters the pump at the bottom through a bell-shaped part called the suction bell. From there it moves into the first stage impeller, which raises the water’s velocity. The water then enters the diffuser bowl immediately above the impeller, where this high velocity energy is converted into high pressure. The bowl also directs the fluid into the next impeller located immediately above the bowl, and this process continues through all of the stages of the pump.

After the water leaves the last diffuser bowl, it passes through a long vertical column pipe as it rises up the well bore toward the surface. The spinning shaft inside this column is supported at three- or five-foot intervals with sleeve bushings that are mounted inside the column and lubricated by the water moving past them. At the surface is the pump discharge head, which allows the flow to change direction, toward the discharge pipe. A vertical high thrust A.C. motor is mounted above the discharge head.

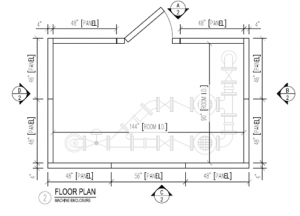

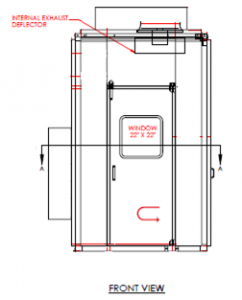

Sound enclosures are typically needed for vertical turbine pumps located near residential neighborhoods, Hospitals, Schools, and other sound sensitive areas. The sound enclosure used can be designed in several different configurations. Most VTP sound enclosures are custom designed built to fit the customer’s needs. I will show sample drawings of the many different types of designs available and what options can be provided. Typical sound reductions from the installation of a four-sided sound enclosure with roof and silenced intake and exhaust forced air ventilation is in the range of 20-30 dBA reduction.

Sound Enclosure Applications

In most VTP sound enclosure applications, the main factor that dictates the design is access to the equipment for maintenance. This access can be achieved in several ways.

Lift Off Sound Enclosure – the sound enclosure is designed with a structural steel internal framework, with lifting lugs on the roof. The acoustical panels and door are mounted to the frame and the enclosure is designed to be lifted off the pump(s) with a crane in one piece.

Lift Off Roof Panels – The sound enclosure’s roof is designed to be easily removed with lifting lugs mounted to each of the roof panels or the entire roof with a structural frame. The panels or roof can be lifted off with a crane for major maintenance.

Removable Panels – The sound enclosure is designed with a stand-alone frame and all the acoustical panels are removable with ¼ turn fasteners. This enables you to quickly disassemble the enclosure walls to obtain access to the pumps.

Doors and Hatches – Double doors, Multiple doors and Roof Hatches are the easiest way to access the pump equipment and motor.

Ventilation – The Vertical Turbine Pumps are typically 100 to 800 horsepower. This size of motor will need forced air ventilation to cool an enclosed pump. We will size the ventilation fan(s) to meet the required airflow and provide silenced are intake air with the use of acoustical silencers, elbow silencers and/or acoustical louvers that will provide the same transmission loss as the wall panels. This ensures the noise reduction goals will be met.

Let us assist you in your noise control needs. Please give us a call at 888-417-1903 or send us an email to info@enoisecontrol.com.