Vacuum Pump Sound Reduction

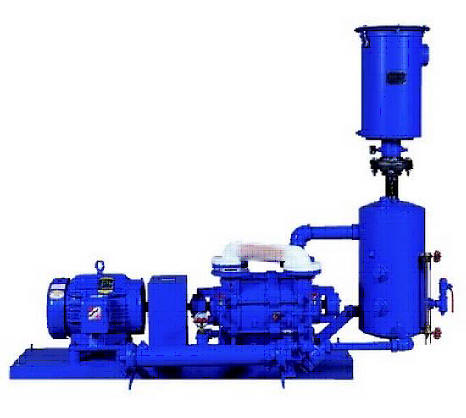

Vacuum pumps, similar to positive displacement (PD) blowers, are a major noise creator in industry today. Typically used for bulk material handling, vacuum pump noise and/or vacuum pump noise control should be considered before installing this type of equipment. The first consideration is where to locate the Vacuum Pump to limit the noise exposure to plant workers. A dedicated vacuum pump noise room constructed of common building materials such as stud wall or CMU construction lined with inexpensive acoustical absorption would typically provide a good solution to the sound issue. Also, sound enclosures are typically available through the original equipment manufacturer or Vacuum pump sales representative. Relocating the vacuum pump away from plant employees, or if outdoor, out of line of sight from complaining neighbors could be an option. If these solutions are not practical or you already have a vacuum pump installed, there are several options available for sound reduction.

When considering sound reduction products, it is helpful to have several items in mind.

- What is the current sound level of the equipment?

- How much noise reduction do I need to reach my goal?

- Where is the vacuum pump currently located?

- What type of access is required to maintain the equipment?

- How much air flow is needed to cool the vacuum pump and motor?

Sound enclosures, noise reduction blankets, sound curtain noise barriers, or sound barrier walls are a few options to consider when reviewing noise reduction materials. If the vacuum pump is indoors, a noise enclosure would be the recommended solution. This sound enclosure can be constructed of noise reduction materials or noise reduction products such as sound curtains or steel sound enclosure panels. The overall sound reduction you achieve from adding acoustic enclosures will be a direct result of what sound reduction materials you selected.

Sound Curtain acoustic enclosures consist of a composite of a mass loaded vinyl noise barrier bonded to sound absorptive noise insulation. The panels are suspended from a floor mounted or ceiling suspended track system. The sound curtain panels ride on the track by means of hook and trolley and the panel edges are joined by mating velcro to form the walls of the enclosure. A roof, ventilation, and windows can be added to the design.

Steel acoustic vacuum pump enclosures consist of a solid steel outer skin and a perforated steel inner skin filled with noise absorptive sound insulation. The steel acoustic enclosures for vacuum pumps are self supporting and modular for easy of assembly. Options available include a roof, ventilation, doors, and windows. Sound enclosures for vacuum pumps are a proven and effective means of soundproofing.

Outdoor vacuum pump sound abatement is typically achieved with the use of sound barriers. Noise barrier walls are typically constructed of structural steel uprights and the steel noise enclosure panels described above. The sound barrier walls create open top acoustic enclosures around the equipment blocking the unwanted sound from traveling, thus reducing the vacuum pump noise.

Another popular solution is a noise reduction blanket or noise reduction cover. The sound blanket is custom fit to your machinery and wraps around the compressor portion of the unit. This creates noise barriers that reduce noise and effectively sound proof the vacuum pumps.

Whether it is vacuum pump noise enclosures, sound barrier walls, or a sound blanket, all are a viable option for noise abatement and sound proofing your facility and community.