Industrial and Utilities Noise Control

The average sound level in a manufacturing facility varies greatly depending on what they are producing. Typically there are always one or two operations or processes that are the noisiest. Employees avoid these areas and do not want to work in them. Source noise control helps employers to limit the exposure to the rest of the facility using the Noise – Path – Receiver methodology of blocking the noise by disrupting the path of the noise before it reaches the noise receivers.

The average sound level in a manufacturing facility varies greatly depending on what they are producing. Typically there are always one or two operations or processes that are the noisiest. Employees avoid these areas and do not want to work in them. Source noise control helps employers to limit the exposure to the rest of the facility using the Noise – Path – Receiver methodology of blocking the noise by disrupting the path of the noise before it reaches the noise receivers.

This can be done with sound barriers, acoustic enclosures, silencers, walls, curtains, and other means of application specific sound attenuation methods. After these problem areas are addressed, you may be left with many machines and processes that are not extremely noisy on their own, but when coupled with many other similar noise level machines and/or operations along with hard, flat noise reflective surfaces that make up a Manufacturing facility, such as concrete floors, metal deck ceilings, and painted concrete block or corrugated metal walls. These conditions make for a facility that propagates high noise levels which leads to hearing conservation programs and mandatory hearing protection. The solution to this condition is to add acoustical absorption to the space. The sound absorptive materials reduce the reflective noise that is bouncing off the walls, floors, and ceilings and reduces overall sound levels in the facility.

A sound absorber is typically a soft porous, open celled material such as a sheet of foam, fiberglass panel, or acoustic baffle that reduces the reflection of sound waves off of hard surfaces. Adding these materials to the plant walls and ceiling has been widely recommended as a proven method of reducing reflected noise for many years. Most of these sound absorption products were initially designed for music rooms and concert halls. Today we have several choices to stand up to the rigors and abuses of an industrial facility.

Sound Curtain Wall Absorbers

The rugged, industrial diamond stitched facing that can be attached to any wall or ceiling. Cuts and mends easily in the field to fit around piping and conduit. Grommets for suspension as needed to be fastened to metal ceiling decks out of the wall of fire protection sprinklers and lighting.

The rugged, industrial diamond stitched facing that can be attached to any wall or ceiling. Cuts and mends easily in the field to fit around piping and conduit. Grommets for suspension as needed to be fastened to metal ceiling decks out of the wall of fire protection sprinklers and lighting.

Acoustical Baffles

Acoustical baffles are PVC faced and the lowest cost per square foot sound absorber. Easily installed on metal decking and open web trusses.

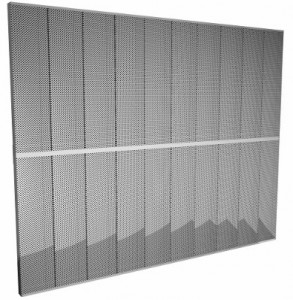

Perforated Metal Wall Panel Absorber

High abuse metal acoustical panels for long term use in harsh environments. Very effective and time tested solution.

eNoise Control can assist you in selecting the lowest cost and most effective material for your noise control application and assist in calculating the correct amount of material to add to your manufacturing space. Please call for a consultation.