Acoustic Foam for Noise Control

You have a noisy piece of equipment – Genset, compressor, pump, etc.

The most cost effective solution to this noise issue is to place the equipment in a box of bent sheet metal and cover the inside with acoustical composite foam. If your equipment is already in an enclosure, you will achieve additional sound reduction with the installation of acoustic foam inside the noise enclosure.

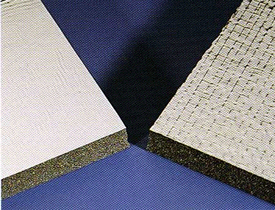

Acoustic foam can be cut to a thickness that matches your needs; most orders are between 1 and 4 inches thick. Foam is available with a convoluted (eggcrate) or flat face. Facing films, such as aluminized mylar and black grey Urethane, can cover the flat faced foam to protect the acoustic foam from damage and moisture.

Adhesive (PSA) backing can be applied for ease of installation. The foam cuts easily with a utility knife in the field or can be die cut to match your specifications. Construction adhesive or spray adhesive are the most popular mounting methods.

If you need assistance on what acoustical foam products would be best for you, check out our acoustical consultant services or call eNoise Control to discuss your acoustic foam project today: 800-213-4711.