Cooling Tower Sound Wall

eNoise Control partnered with an engineer firm working on a noise solution for a large cooling tower assembly for a PA Energy Center being built. The Energy Center has residences in close proximity to the building site. This was a concern for the owner and the neighbors. We proposed a Sound Wall to partially cover three sides of the unit and the barrier wall to be a sufficient height to block line of sight to nearby homes.

The acoustical panels specified were 4 inches thick with a solid galvanized steel exterior shell and a perforated/solid galvanized steel inner shell. The panels were connected by means of a tongue and groove connection. The panel shells framing members, and internal reinforcements are welded together to form a metal-sheathed panel of sufficient strength for maximum operating loads. The outer galvanized steel shell thickness is 16 ga. and the inner galvanized steel shell is 22 gauge minimum thick. Where perforated materials are indicated, all perforations are 3/32” dia. holes on 3/16” staggered centers and shall result in an open area of no less than 23 percent. All panel internal and external reinforcing members are 18 ga. galvanized steel.

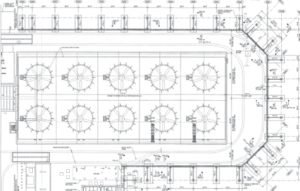

The engineering firm designed the structural steel support frame for the acoustical panels. The sound wall was approximately 300’ x 180’ x 36’ high with structural steel vertical columns and angle supports. Cross members were used as structure to attach the acoustical panels to the inside face of the wall with the perforated (sound absorptive side facing the cooling tower.

The construction and installation of the sound wall was a complete success with the owner and neighbors happy with the results. Please contact eNoise Control inc. to discuss your noise control project.