Acoustic Foam is proven as an effective noise control product that has been in use for decades. Polyurethane, polyester, and melamine acoustic foams are used in many different industries for acoustics and noise control. These products are seen on the walls in recording studios and on the ceilings of music venues, but you typically never see the places where foam products are used the most – Sound Enclosures. Many OEMs (Original Equipment Manufacturer) fabricate or have fabricated dedicated sound enclosures for their standard noisy equipment. They are typically made from sheet metal and spot welded or mechanically fastened together to form an enclosure around the equipment and function as a protective shell. The enclosures are lined on the inside with acoustical foam of varying thickness.

The outer skin of the enclosure is the sound barrier and the inner lining on the acoustic foam is the sound absorber. The two parts create a composite assembly for superior noise control.

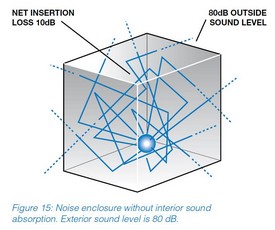

When noisy equipment is enclosed in a hard, flat, reflective enclosure, the sound energy reflects off the walls, floor, and ceiling of the enclosure and the levels inside the enclosure actually become louder. By adding acoustical foam to the inside of the sound enclosure, the reflected noise is reduced both inside and outside of the sound enclosure.

For Example: If a noise source sound level is 90 dB and it is enclosed with a sheet metal enclosure having an insertion loss of 20 dB, the sound within the enclosure would increase to 100 dB (Figure 15). The sound level outside the enclosure would be 80 dB instead of the expected 70 dB. By adding acoustic foam to the inside of the sound enclosure, the sound levels will NOT increase inside the enclosure and you will achieve the 20 dB reduction outside of the enclosure (Figure 16).