Acoustic Blanket Specifications

Acoustic blankets are excellent noise control solutions for a variety of HVAC machinery. This product is often referred to as an acoustic jacket, wrap, or suppression blankets. These flexible blankets are custom fit for the manufacturer and model of the equipment. Resistance to chemicals and inclement weather make them ideal for all indoor and outdoor applications. Installation is easy and the blankets are removable to allow for quick equipment service and maintenance.

Acoustic blankets are excellent noise control solutions for a variety of HVAC machinery. This product is often referred to as an acoustic jacket, wrap, or suppression blankets. These flexible blankets are custom fit for the manufacturer and model of the equipment. Resistance to chemicals and inclement weather make them ideal for all indoor and outdoor applications. Installation is easy and the blankets are removable to allow for quick equipment service and maintenance.

Common Applications

We have experience with many of the following pieces of equipment and specifically with models from Trane, York, Carrier, and McQuay. The products are designed to fit your make and model to ensure an excellent fit.

- Rotary Screw Chiller

- Centrifugal Liquid Chiller

- Reciprocating Compressor

- Blower

- Motor Housing

- Gear Box

- Fan Housing

- Piping and Fittings

- Oil Separator

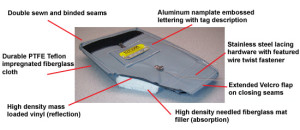

Blanket Composition

- Outer and inner jacketing of 16.5 ounce/square yard PTFE Teflon Impregnated Fiberglass Cloth

- Interior sound absorption material of 11 PCF Fiberglass Needled Mat-Type “E” Fiber

- Sound reflector of barium sulfate loaded vinyl

- PTFE Teflon Cloth Jacketing to encapsulate the sound absorber and reflector materials

- Fasteners allow for easy installation and removal

Blanket Construction

- Double sewn lock stitch with minimum of 7 stitches per inch

- Raw edges have tri-fold PTFE Teflon cloth binding

- Stitching with Teflon thread

- Blanket seams overlap mating flanges or butt up to existing insulation to minimize open gaps

- Aluminum nameplates on each blanket piece to identify item location, description, size, and pressure rating

- Quilting pins prevent shifting of insulation