Summary of MSHA Noise Guidelines

Mining poses many hazards to workers, one of which is noise induced hearing loss (NIHL). According to the Centers for Disease Control and Prevention (CDC), 25% of mine workers suffer from a hearing problem. Furthermore, 76% are exposed to hazardous levels of noise – the highest incidence in all major industries – and 80% will have some type of hearing problem by the time they reach their 60s.

Left unaddressed, NIHL can affect not only the miners themselves, but also their ability to safely and effectively perform their work. They can experience difficulties communicating with coworkers or be unable to hear danger warnings and act accordingly. They may also complain of tinnitus, or a persistent ringing in the ears despite the absence of noise. This can significantly hinder their ability to be productive.

To reduce the risk of NIHL for miners and to ensure that mining companies are actively protecting their workers from hazardous levels of noise, the U.S. Department of Labor’s Mine Safety and Health Administration (MSHA) issued a compliance guide to its revised occupational noise exposure standard in the year 2000. The guide is intended for use by all parties in the mining industry – operators, workers, worker representatives, mines in all locations and of all sizes – and its most salient points are as follows.

Title 30 of the Code of Federal Regulations outlines rules and standards pertaining to the mining industry.

The 3 Levels of Noise Exposure

1) Action Level

If workers are exposed to what MSHA defines as “action levels” of noise, you (the employer) are required to enroll them in a hearing conservation program (HCP) that complies with the guidelines under Section 62.150. The requirement applies to operators of coal mines, metal mines, and nonmetal mines.

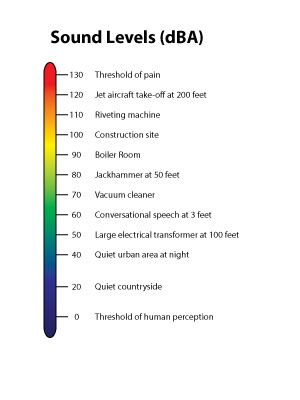

Per MSHA’s guidelines, a miner’s noise exposure is “action level” when it meets or exceeds an 8-hour time weighted average (TWA) of 85 dBA, accounting for sound levels between 80 dBA to 130 dBA.

2) Permissible Exposure Level

If workers’ noise exposure levels meet or exceed an 8-hour time weighted average of 90 dBA, accounting for sound levels between 90 dBA to 140 dBA, the noise falls under the Permissible Exposure Level (PEL).

In this case, you must not only enroll your miners in an HCP, but also use all feasible engineering and administrative controls to reduce noise to a PEL. These controls include, but are not limited to the below actions.

- Using hearing protectors for individual miners

- Posting administrative controls on the workplace’s bulletin board

- Providing a copy of the above mentioned controls to the miners

3) Dual Hearing Protection Level

If workers’ noise exposure levels meet or exceed an 8-hour time weighted average of 105 dBA, accounting for sound levels between 90 dBA to 140 dBA, the noise falls under the Dual Hearing Protection Level.

At this level, you must provide muff- and plug-type hearing protectors in addition to the requirements specified for noise exposure that meets or exceeds a PEL.

Maximum Exposure Level

Aside from the 3 levels of noise exposure, the MSHA also specifies a maximum exposure level of 115 dBA. If miners experience this level of noise, you must take all of the necessary steps to reduce it, even if your miners already use hearing protectors.

Engineering and Administrative Controls

Previously, MSHA’s provisions on engineering and administrative controls applied only to metal and nonmetal mine operators. Now, the provisions apply to all mine operators, as laid out under Section 62.130.

You may choose to implement engineering controls, administrative controls, or a combination of both. As long as the selected controls cut workplace noise down to a PEL, the MSHA will consider an operator compliant with its standards.

If one type of control fails to adequately reduce miners’ noise exposure, you must use a combination of engineering and administrative controls. The National Institute for Occupational Safety and Health (NIOSH) defines engineering controls as those that “isolate the noise from the worker through noise reduction” and administrative controls as those that “isolate the worker from noise by reducing exposure.”

Generally, administrative controls fall under one of 4 categories:

- Job switching or rotation,

- Relocation of workers from high-noise to low-noise areas,

- Modification of tasks to reduce noise exposure, and

- Equipment operation.

Depending on the type of mine, the specific implementation of these controls may vary.

Some controls fall under the administrative and engineering categories, such as the following.

- Use the quietest equipment available.

- Maintain equipment to prevent noise from going beyond permissible levels.

- Keep noise sources away from areas with heavy foot traffic.

- Require workers to use sound-treated booths.

Once administrative controls are put into place, the MSHA requires you to post the procedures on the workplace bulletin board or in any other easily accessible place and provide a copy of those procedures to your workers.

What if the controls are unable to reduce noise to permissible levels?

If you have exhausted all possible options to reduce noise in your workplace and your miners’ exposure levels still meet or exceed the permissible number, the MSHA recommends you continue to implement such controls. Additionally, you should

- provide and require the use of hearing protectors,

- enroll workers in hearing conservation programs, and

- post administrative procedures on the bulletin board and provide a copy to workers.

As long as these measures are in place, the MSHA will not sanction an operator for failing to comply with the required PEL. However, the use of hearing protectors in lieu of engineering and administrative noise controls does not qualify as compliant with MSHA standards.

In what instances will the MSHA issue citations or take action?

If an operator fails to comply with the provisions under Section 62.130(a) or has not exhausted all feasible means to reduce miners’ noise exposure levels, the MSHA will issue the appropriate sanctions.

If an operator has exhausted all feasible means for noise control and exposure levels still meet or exceed the PEL, the MSHA will work together with the operator to develop the best possible noise reduction program for miners.

What makes an engineering or administrative control “feasible”?

The MSHA considers an engineering or administrative control feasible when it reduces noise exposure and is technologically and economically achievable. To assess the feasibility of a control, the MSHA also considers the following factors:

- the nature and degree of noise exposure,

- the demonstrable effectiveness of the available technology in reducing noise, and

- the amount of resources invested into the noise control program with regard to the expected results.

If the last standard mentioned above is not met, the MSHA considers it adequate grounds for issuing the appropriate citations.

Are noise levels in the mine required to be below the PEL?

Noise levels in the mine are not necessarily required to be below the PEL. As long as controls can reduce overall noise levels by 3 dBA or more, that is considered sufficient. If, for example, an engineering control only cuts noise by 2 dBA but can bump up the reduction to 4 dBA when combined with an administrative control, the controls are considered feasible.

Also, a 3 dBA noise reduction does not necessarily have to cover all frequency ranges. If the control reduces noise by 3 dBA in only one frequency band, the control is still considered adequate. Again, as long as all possible options for noise control are exhausted, the MSHA will not issue citations.

How can operators measure noise exposure levels?

Under Section 62.110, a mine operator must establish a noise monitoring system to evaluate miners’ exposure levels and compliance with MSHA standards. The operator may choose any system they wish as long as it can accurately and adequately address the following items.

- Calculate whether noise exposure levels meet or exceed the 85 dBA action level, the 90 dBA permissible exposure level, or the 105 dBA dual hearing protection level.

- Determine the efficacy of the existing administrative and engineering controls.

- Identify mining location where hearing protectors are most needed.

- Provide information to the audiometric testers regarding the results of miners’ audiograms.

To accurately measure individual miners’ noise doses, the noise exposure level must be calculated using:

- the 90 dB criterion level,

- the 5 dB exchange rate,

- the slow response and A-weighting instrument settings,

- an integration of all sound levels over the appropriate range, depending on the type of noise level (action, permissible exposure, or dual hearing protection) to be measured,

- the best number of hours to reflect a miner’s full work shift, and

- the noise level experienced by the miner when not using hearing protection.

The most common instruments used to measure noise are sound level meters and noise dosimeters. The MSHA makes its evaluations based on data collected from personal noise dosimeters. However, sound level meters may also be used to identify noise sources and complete noise surveys in the workplace.

What role do the miners play?

According to Section 62.110(c), you are required to notify miners about the date and time they are to be monitored and to allow them to observe the necessary monitoring activities. You are also required to notify them about whether their noise exposure meets or exceeds allowable levels within 15 calendar days after monitoring as per the guidelines specified under Section 62.110(d). However, you are under no obligation to give them or their representatives monetary compensation for the same.

To comply with MSHA standards, and, more importantly, to keep your miners in optimal health, no expense should be spared. Your compliance with MSHA noise guidelines will significantly impact your company in the long run.

For more information on noise control, noise control equipment, and sound surveys, contact eNoise Control for a consultation today. We can be reached at at 888.417.1903 or send us an email to info@enoisecontrol.com.