Machine Enclosure Acoustic Foam

Machine Enclosure Acoustic Foam

Machine Enclosure Acoustic Foam is commonly used in lining OEM equipment manufacturer’s existing machine enclosures. Compressors, generators, paper printing, slitting and folding machines – these are all examples of applications that utilize acoustic foam and sound enclosures. Typically this equipment is supplied enclosed within factory-fabricated, steel enclosures with doors for access to the equipment. This factory installed solution is adequate for most applications. Equipment that generates higher noise levels may require additional insulation added to the inside of the standard manufacturer’s enclosure. Adding acoustic foam increases the noise reduction performance of a standard OEM enclosure significantly.

Complete Product Selection:

- Polyurethane Foam Panels and Baffles

- Melamine (MFX) Foam Panels and Baffles

- Ceiling Tiles

- Acoustical Composites

- Barriers

- Foam Treatments

Machine Enclosure Acoustic Foam

Acoustical foams are designed to provide maximum absorption of airborne sound with minimum thickness and weight. These flexible open-cell foam products are manufactured to optimize pore size, airflow resistance, and density.

Sound energy, passing through the cell structure of the foam, is converted into minute quantities of low grade heat that is easily dissipated. Since the uniformity of the cells is carefully controlled the acoustic performance is predictable from one installation to another.

Many applications require foam products to be subjected to environments such as dirt, moisture, chemicals, oils and abrasion that could be hostile to unprotected foam. Various surface treatments are available to protect the integrity of the foam from harsh elements. These facings will increase the absorption properties – at certain frequencies – as well as provide a cleanable, and if desired, color-coordinated, yet durable finish for a wide variety of applications.

Acoustic Foam Panels and baffles are quick and easy to install.

Our acoustical foam panels and hanging baffles can be used to absorb various types of noise in nearly every environment. All of our products are independently tested to determine their sound-absorbing and fire-rating specifications. (See individual product specifications for details.) Independent laboratory testing will ensure that each product you receive will perform the way you expected.

Our polyurethane acoustical foam panels and hanging baffles can be used to absorb various types of noise in nearly every environment. Panels install easily on walls and ceilings to handle the toughest noise problems. Baffles can be hung to interrupt and absorb free-floating noise.

This makes them ideal for big indoor areas with hard surfaces, such as: gyms, manufacturing areas, auditoriums, and indoor swimming pools. Baffles also offer the advantage of being moveable and they control noise coming from every direction.

Features of Polyurethane Foam Panels & Baffles:

- Open-cell polyurethane construction for maximum noise control

- Flammability ratings

- 1″ to 8″ thicknesses for precise level of sound control

- Easy installation of panels or baffles

- Baffles are moveable and control noise coming from every direction

Versatile Products with Multiple Application Possibilities:

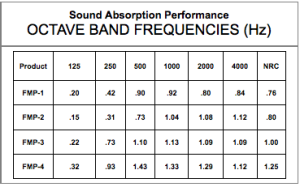

- Sound Absorption Performance

- OCTAVE BAND FREQUENCIES (Hz)

- Industrial noise control

- Commercial, home and audio market

- Firing ranges

- In-Plant manufacturing noise

- Metalworking operations

- Gymnasiums

We offer a complete range of acoustical foam composites.

Our products range from cost-effective, pre-designed acoustical foam

to custom wedges and other profiles.

Sound Absorption Performance: